Given the high value of the metals contained in electric vehicle (EV) batteries, there are strong market incentives to improve the circularity of battery supply chains. This is creating an opportunity for Canadian battery recycling innovators to position themselves as clean, cost-competitive partners to existing battery supply chain actors.

by Ken Hendricks

As EV adoption rises, questions are being asked about how EV batteries will be managed at their end-of-vehicle life. EV batteries are not like other consumer batteries or electronics. They require different policies and programs to manage them.

In December 2022, Transport Canada published Canada’s Action Plan for Clean On-Road Transportation, which identifies the key challenges involved with shifting the motoring public to electric vehicle use, including the production and end-of-life management of EV batteries. Working with the provinces and territories, as well as industry stakeholders, the Government of Canada is planning to develop national guidelines for managing electric vehicle batteries in an environmentally-sound way. The government will also be speaking with provinces and territories to explore the merits of a national approach to managing electric vehicle batteries at end of life.

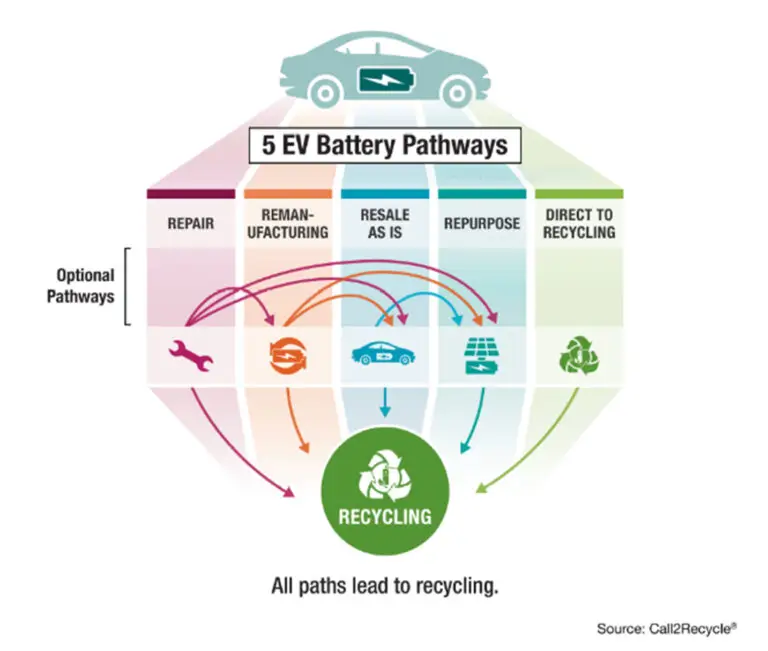

There are five essential potential pathways for EV batteries:

- Repair

- Remanufacturing

- Re-sale as is

- Repurposing (second-life)

- Recycling

Ultimately, all pathways lead to recycling. The recycling of critical minerals (lithium, nickel, cobalt, manganese, graphite, copper, and aluminum) used in the manufacturing of new batteries will reduce the demand for new materials and help reduce the costs of manufacturing EVs. But what criteria or standards will be used to determine a battery’s life cycle and when or how a battery is to be re-used, repurposed, repaired, or ultimately recycled?

The federal government has been working with the provinces of British Columbia and Quebec, the state of California and other like-minded jurisdictions outside of Canada, and with other Canadian stakeholders, to make sure that all are moving in the same direction in the move to zero-emission vehicles (ZEV). B.C. has announced its intention to implement an extended producer responsibility (EPR) program for EV batteries by 2026, and California has completed its roadmap for developing a battery management system.

With the intent of sharing best practices and lessons learned, federal, provincial, and territorial governments continue to work together through a Zero-Emission Vehicle Working Group, co-chaired by the Government of Canada and the Government of British Columbia. This working group meets quarterly and has been key to aligning Canada’s zero-emission vehicle policies and identifying other areas where governments can work together.

Similarly, the Canadian Vehicle Manufacturers in partnership with Call2Recycle has published its Electric Vehicle Battery Management at End-of-Vehicle Life Primer. Within the Primer are recommendations “designed to help support the development of a robust, efficient, and environmentally sustainable circular economy for EV batteries, address misconceptions and close the knowledge gap that still exists with respect to the collection and management of EV batteries at end-of-vehicle life.”

It would be a mistake for anyone in the automotive industry (especially if their business is aligned to any centralized EV battery management system) to think that all things will be equal in the future. There are many questions that remain, but they will hopefully be sorted out as we work through these problems.

First, there is the challenge of establishing clear standards for aiding in the decision to re-use, repair, remanufacture, or recycle a warranty or an out-of-warranty battery. Market forces will obviously have a significant role to play here, but there will be other factors that will need to be accounted for. These may include such things as access to repair information, the need to address things such as critical mineral supply shortages, technical and training qualifications, secondary battery storage, health and safety issues, etc. It may also become important to define legal roles and responsibilities especially under an EPR framework. For instance, who is ultimately responsible for the end-of-life of a product? Does legal responsibility remain with the producer throughout a battery’s life cycle, or will it be transferred to a third-party for such things as remanufacturing, repurposing, or those engaged in the repair or modification of an EV battery?

The ARA is working diligently with the provincial government on all these issues, as well as with other federal and provincial stakeholder partners. B.C. has become an EV adoption leader in North America, yet even B.C. lags behind many European countries (such as Norway and Germany) in terms of EV adoption rates. Norway has recently announced that it has achieved an 80% EV adoption rate, and EVs have reached 55% of all new vehicles sales in Germany. Current estimates place B.C. at about 19%, and the province is well on its way to meeting provincial targets for 2030 and 2035.

The ARA has been diligently working on several EV projects over the past few of years to help industry deal with the transition to EVs and position our members for future entrepreneurial success. This includes the EVfriendly program and training initiatives, which have been up and running now for the last year. We are currently engaged in a sector labour market project, which is involved in researching the impact that electric/autonomous vehicles will have on the labour market. A full report will be released in the spring. We are also restructuring the recycling environmental audit program to help bring it in line with changes to the end-of-life processing of electric vehicles.

The face of the industry is changing rapidly, and while technological transformation eliminates the old ways of doing things, new opportunities will emerge. It is important for industry and for those who work in it to stay abreast of these changes, to become engaged with the world through professional associations (like the ARA), to learn, and to look for opportunities to capitalize on these changes.