Explore the road to profitability and return on investment in this highly competitive industry.

Let’s start this conversation by asking a few questions. How many owners of independent automotive service facilities will have made enough money to retire by the time they are 65 years of age? How many shop owners could sell their businesses in the next five to 10 years for a profit? Besides making a living, did any shop owners get a return on their investment?

I know the answer for some is yes, but for the majority of shop owners I meet, the answer would have to be no. This is a hard thing to face and to talk about. The most common question we ask each other in this industry is: “How busy are you?” What does busy mean? Does it mean that we have a lot of cars to work on, or does it mean that the owner is busy putting out fires? The questions should be: How are your profits? What are your returns? Do you have time off, and what is your stress level like?

Many times in life, we are so busy doing that we don’t have time to plan. We are so focused on the task at hand that we don’t look to the horizon of the future. By saying we are busy at our shop, we usually mean that we have lots of sales, or at least a lot of cars going through the shop. How is it then that when we look at our bank account or our balance sheet, we wonder where all the money is? We may ask our accountant, and they may say, “cut costs,” and we wonder where to cut from.

A while ago I heard a great saying, “It does not matter how much money you take in; it matters how much you keep.” It seems obvious, but like many things in life, this is hard to accomplish. How can a shop with annual sales of a million dollars not show a profit at the end of the year? The reason is this—the owner focused on sales, not on productivity, gross profit, net profit, return on investment, and good tax planning.

In my last two articles, I discussed how to achieve net profits of 20%, and to accomplish those net profits, a shop needs a gross profit of 60%, and in order to achieve those gross profits, we need a technician productivity of 90%.

As I review those articles, I see that I have only touched on technician productivity, and this needs an in-depth study. I have mentioned the statistic that the average technician in the industry is only 54% productive, and I gave you a lot of hints on how to keep a technician productive by selling every tenth of a minute. Because we want to retire well, we need to become experts at implementing this practice.

And before all the technicians reading this article get upset by the statistics, we need to understand that productivity is primarily management’s responsibility. Technicians are primarily responsible for efficiency. Let me give you some definitions to clarify. “Productivity is the ratio between how many hours a technician is available every day compared to how many hours management was able to keep him working on cars.”

Here is an example—if a technician is available for eight hours, and they worked on vehicles for six hours, they were 75% productive. The other key factor is that management charge the clients for all those hours. “Efficiency is how long it takes a technician to do a job compared to how long it was sold for.” For example, if a technician is assigned a work order that has four sold hours on it, and they do it in three hours, they are 133% efficient. The benchmarks we use in our training are 90% productivity and 125% efficiency.

Another way to look at this and succeed is to look at each hour that a technician is available as an inventory item. Because the majority of independent shops pay hourly, shop owners have already purchased eight hours at the beginning of each day. But unlike mechanical parts, they cannot be sold tomorrow if they are not sold today. The question we should be asking each other is not how busy we are, but “Have you sold your entire labour inventory today?”

Many shop owners try to hold technicians accountable by measuring the number of hours they bill in a day, yet both the owner and technician wonder why it never gets past a certain amount. Let’s look at the technician who billed six hours out of an eight-hour day. What happened to the lost 2 hours? How much time was spent by the technician ordering parts, looking up labour times, performing free parking lot diagnosis, and driving cars in and out of the bays? I could go on and on. Do you see how the technicians are working, just not on the right stuff? Your challenge is to learn the systems and procedures that capture your full labour inventory and sell it all.

Another challenge most shops face when it comes to profitability is discounting. A lesson I learned from a mentor years ago goes as follows: if our goal is to make a 20% net profit, that means that each invoice should have that profit built into it; however, as soon as I offer a 5%, 10%, or even 15% discount off that invoice, I have given away my net profit. And this industry is still only averaging between 5% and 7% net profit.

When we discount a particular invoice, we are working for free. Why do you need to discount? Because the customer has asked? Because you need to compete with other shops? Have you ever asked yourself why customers want a discount? Is it because they don’t have the money? This may be the case at times, but for the most part, it is because they perceive that they are not receiving value for their money.

Oh boy, here comes that value question! How do we pin that down? What is value to the driving public? Four struts for the cost of three? Oil changes for $29.99? Pulling engine codes for free? Believe it or not, this is what we have taught the public to think of as value, but when shops figure it out, they find it was very different from that. Let me list some of them, not necessarily in order of priority:

- The car is returned to the customer cleaner than when it was dropped off.

- The customer is informed about the repair process and kept in control of their money at all times.

- The vehicle is completed when promised.

- The vehicle is fixed right the first time.

- A comprehensive nationwide warranty is made available and explained thoroughly.

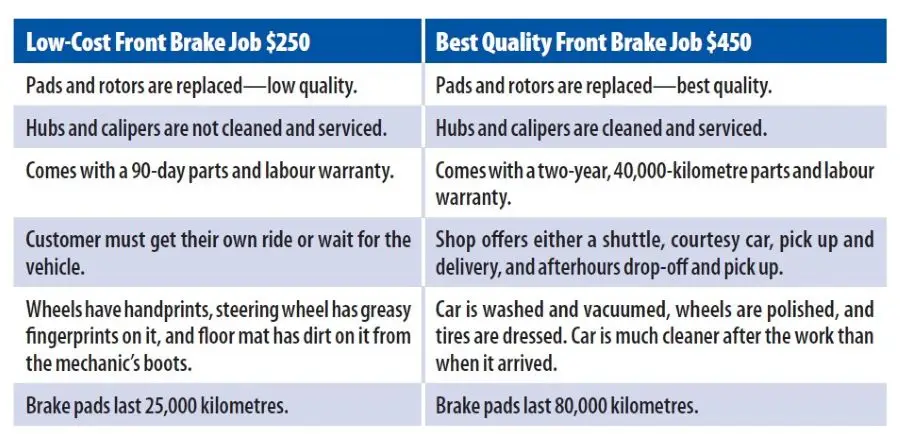

We are happy to solve warranty issues for our customers because they are an inconvenience to our customer and not to us. At the end of the day, the invoice day is the same as the last estimate given. See the graphic example above:

I know of hundreds of shops who carry out these quality practices day in and day out, and the word “discount” never comes up with their clients. Again, we have to use best practices, systems, and procedures to be as organized as we need to be to carry this out.

If you recall, we have been talking about retirement for shop owners, net profit, and return on investment. It is not about how busy we are, or how many cars we work on—it is ultimately about how much money we keep at the end of the day. My challenge to all of you is to rethink how you look at your business. Questions to find answers to are: How do I keep more money at the end of the day, week, month, year, and my career? We let so much of it slip between our fingers on an hourly basis and are not even aware of it. I have given you two areas to work on, technician productivity and reducing discounts. Both should add significantly to your bottom line and your pension fund.

Murray Voth spent 20 years owning and

operating service stations with repair bays.

During that time, he took a lot of training and

participated in a 20-group process for 13 years.

He also provided dealer development training

for several large oil companies. From 2006 to

2018, Murray was head trainer and coach for

a large Canadian automotive aftermarket

training company. In 2018, he formed RPM

Training, and he launched RPM Mastermind

Groups and his Service Management and

Results Training (SMART) course. In March

2020, Murray switched gears and took all

his training, groups, and coaching online.

Currently, business is growing faster than ever

due to all the challenges industry is facing

at this time. RPM Training is now offering

the three-day SMART course live, in-person,

and online.

RPM Training offers a special discount on training courses for ARA members. Visit the ARA’s Preferred Supplier website to take advantage of this offer.